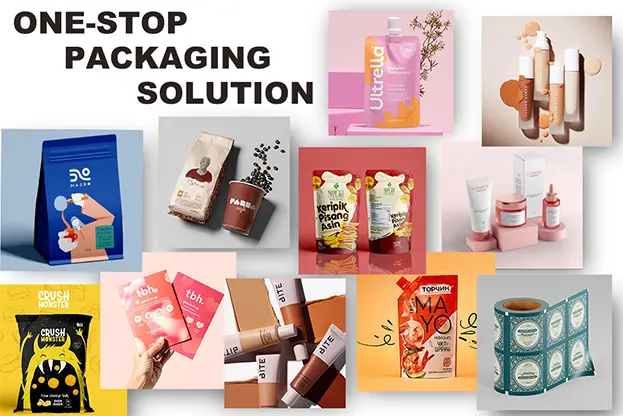

Flexible packaging printing, including flexo and gravure, is transforming the packaging industry with its versatility, efficiency, and advantage in label production. This method offers cost-effective solutions, reduces waste, and provides high-quality results using flexible printing techniques and flexible printing plates. From vibrant colors to intricate designs, flexo flexible packaging printing meets diverse needs across various sectors, including label type. It ensures products stand out on shelves while maintaining print durability and label sustainability using flexo type. Scroll down to discover our top picks and reviews of the best flexo flexible packaging printing and label options available today.

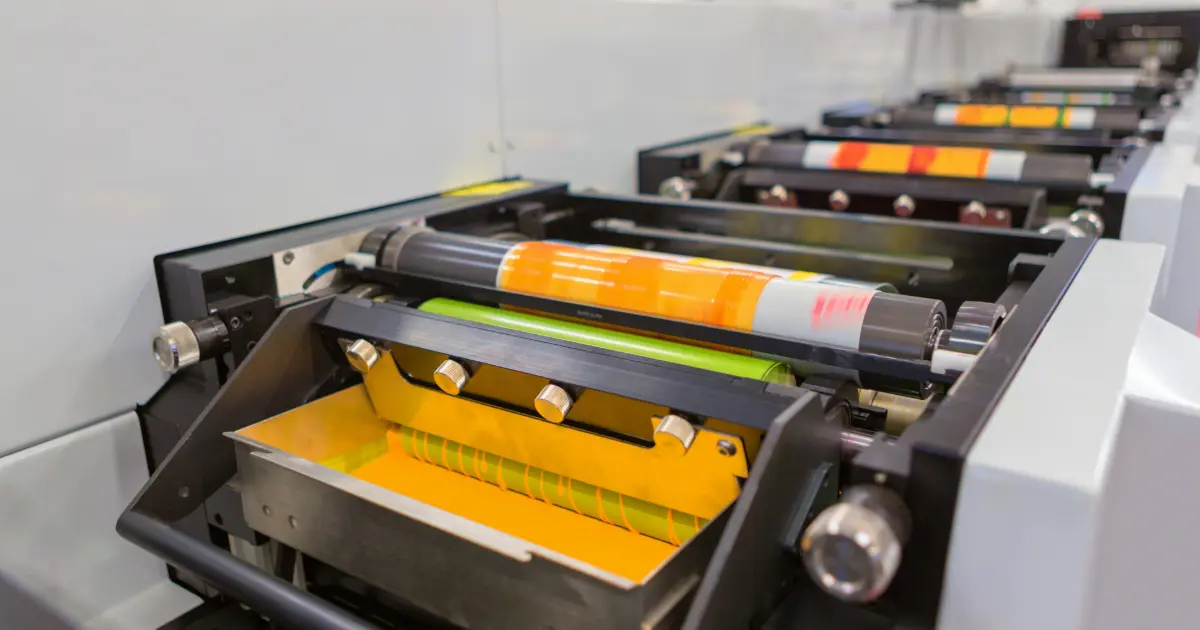

1. Rotogravure Printing

Rotogravure printing excels in high-volume reproduction, making it ideal for long-run magazine and catalog production. This print method uses engraved cylinders to transfer ink onto the substrate, ensuring unparalleled image quality and depth of color. Each cylinder is meticulously engraved with tiny cells that hold the ink for print. When the cylinder rotates, it picks up ink from a fountain roller and transfers it to the print material. This process allows for consistent and high-quality prints. Despite high initial setup costs due to the engraving process, rotogravure printing becomes cost-effective for large orders. The durability of the cylinders means they can be reused for multiple print runs, reducing long-term costs. In the food packaging industry, rotogravure is favored for its ability to print on various materials like films and cartons. Its precise color reproduction ensures that food images look appealing and accurate in print. Printing is extremely fast, with modern machines capable of producing fourteen meters of film in less than a second!

2. Digital Printing

Digital printing is a form of screen printing packaging that uses inkjet technology to apply images and branding components directly to plastic substrates. Digital printing offers unmatched flexibility and speed for short-run, customized packaging solutions. Unlike traditional printing methods, it eliminates the need for plates, which reduces setup time and costs significantly. This makes it ideal for businesses needing quick turnarounds. Digital printing systems can produce high-quality images and text directly from digital files. This ensures that every print is sharp and vibrant, maintaining consistency across all prints. For example, inkjet technology allows for precise color matching and detailed designs on various printing surfaces, providing a superior finish compared to aniline printing. In the print industry, digital printing has become a popular printing technique due to its efficiency and adaptability. It supports a wide range of materials and is perfect for personalized print packaging needs.

3. Flexography Printing

Flexography printing, often called flexo, is a widely used and efficient printing method. It uses flexible plates made of rubber or plastic, which are wrapped around cylinders on a press. These plates can print continuously at high speeds, making the process ideal for large-scale jobs.

The process starts with creating a master plate that holds the image to be printed. This plate is coated with fast-drying, low-viscosity inks that transfer the image onto various materials. Flexo can print on many surfaces, including paper, plastic, and metallic films, which makes it very versatile.

4. Offset Printing

Offset printing offers precision and high-quality output for flexible packaging. It is ideal for detailed graphic work, ensuring sharp print images and text.

The process uses a printing plate to transfer ink onto paper or other materials. This method supports both CMYK and Pantone colors, which helps maintain print brand consistency.

Using offset lithography, operators can handle medium to large print runs efficiently. The economies of scale make it cost-effective when producing larger print quantities.

Modern advances in printing machines have improved the positioning of sheets, reducing waste. Operators can also adjust the amount of ink applied, ensuring uniformity across all prints.

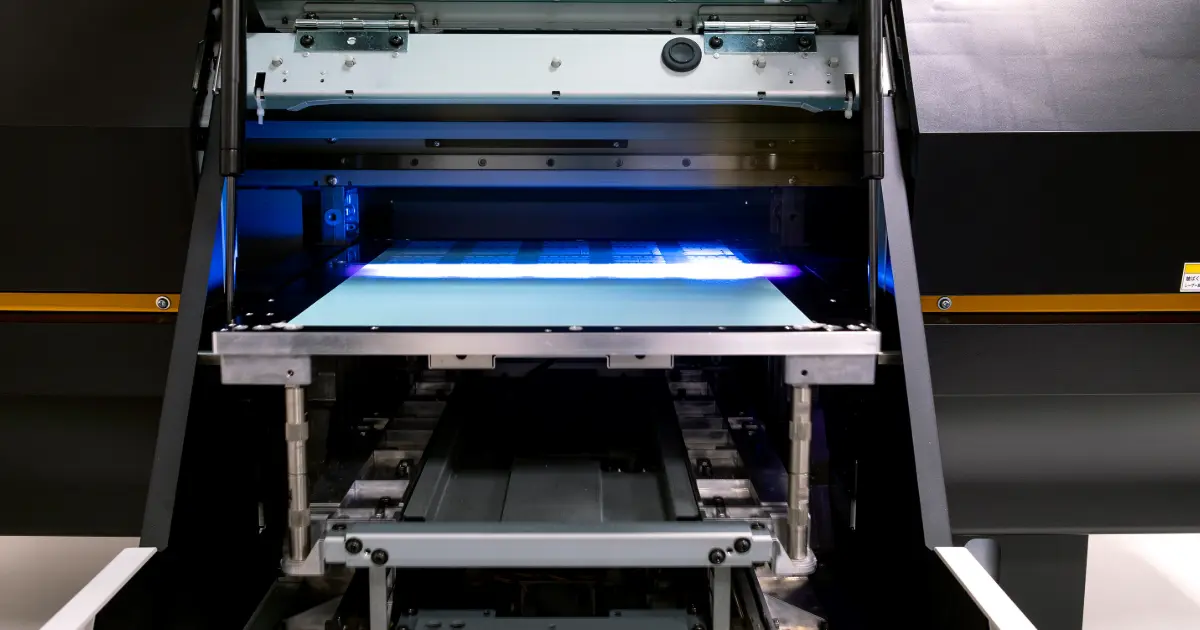

5. UV Printing

UV printing uses ultraviolet light to instantly cure inks, leading to faster production times 및 reduced drying space. This method allows for immediate handling and packaging of printed materials.

The durability of UV printing stands out. It offers resistance to fading, making it ideal for print products exposed to sunlight or harsh conditions. This is crucial for items like outdoor signage 및 product labels that need to withstand environmental stress and print.

Environmentally, UV printing has significant benefits. It produces lower emissions and consumes less energy compared to traditional drying methods. This makes it a more sustainable option for businesses looking to reduce their carbon footprint.

UV printing also employs photopolymer technology, which enhances the quality and precision of the print. The use of photopolymer in the print process ensures sharp and vibrant colors, providing a professional finish.

Summary

플렉시블 패키징 프린팅은 로토그라비어, 디지털 인쇄 및 오프셋 인쇄, 각각 고유한 장점을 제공합니다. 라미네이션, UV 인쇄, 엠보싱, 금속성 잉크, 그리고 무광 마감은 포장의 시각적 및 기능적 매력을 향상시킵니다. 지속 가능한 옵션은 환경 영향을 줄이는 데 점점 더 중요해지고 있습니다.

이러한 방법들은 기업들에게 다양한 요구를 충족시키는 일반적인 솔루션을 제공합니다. 이러한 기술을 도입하면 혁신적이고 친환경적인 포장을 구현할 수 있습니다. 독자들은 이러한 옵션을 더 탐구하고 자신의 프로젝트에 적용해 볼 것을 권장합니다.

제품 포장에 가장 적합한 인쇄 방법을 선택할 때는 사용하는 재료 유형, 디자인 복잡성, 예산 등의 요소를 고려하는 것이 중요합니다. 전문가와 상담하기 맞춤형 유연한 인쇄 포장 백을 제작해 보세요.

디지털 인쇄는 소량 생산과 빠른 납품이 가능합니다. 높은 맞춤화 기능으로 프로모션 아이템이나 한정판에 적합하며, 폐기물과 설정 비용을 줄여줍니다.

라미네이션은 내구성과 차단 특성을 향상시킵니다. 수분, 산소, 빛으로부터 보호하며 유통기한 연장과 포장 외관 개선 효과가 있습니다.