Custom Flat Bottom Pouches | Bottom Gusset Bags

Customize your own Flat Bottom Pouches with Kaleadpack, we provide full options at factory price. Support global shipping.

Customize your own Flat Bottom Pouches with Kaleadpack, we provide full options at factory price. Support global shipping.

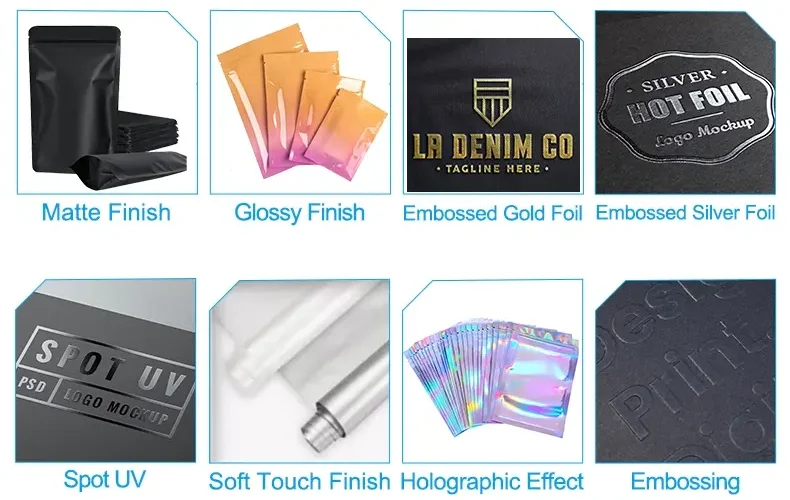

At KaleadPack, we believe that packaging is more than just a protective shell, it’s a statement of your brand’s quality and values. Our wide range of customization options for flat bottom pouches bring your brand’s unique vision to life. Below, you’ll find a visual guide to the myriad of possibilities awaiting you:

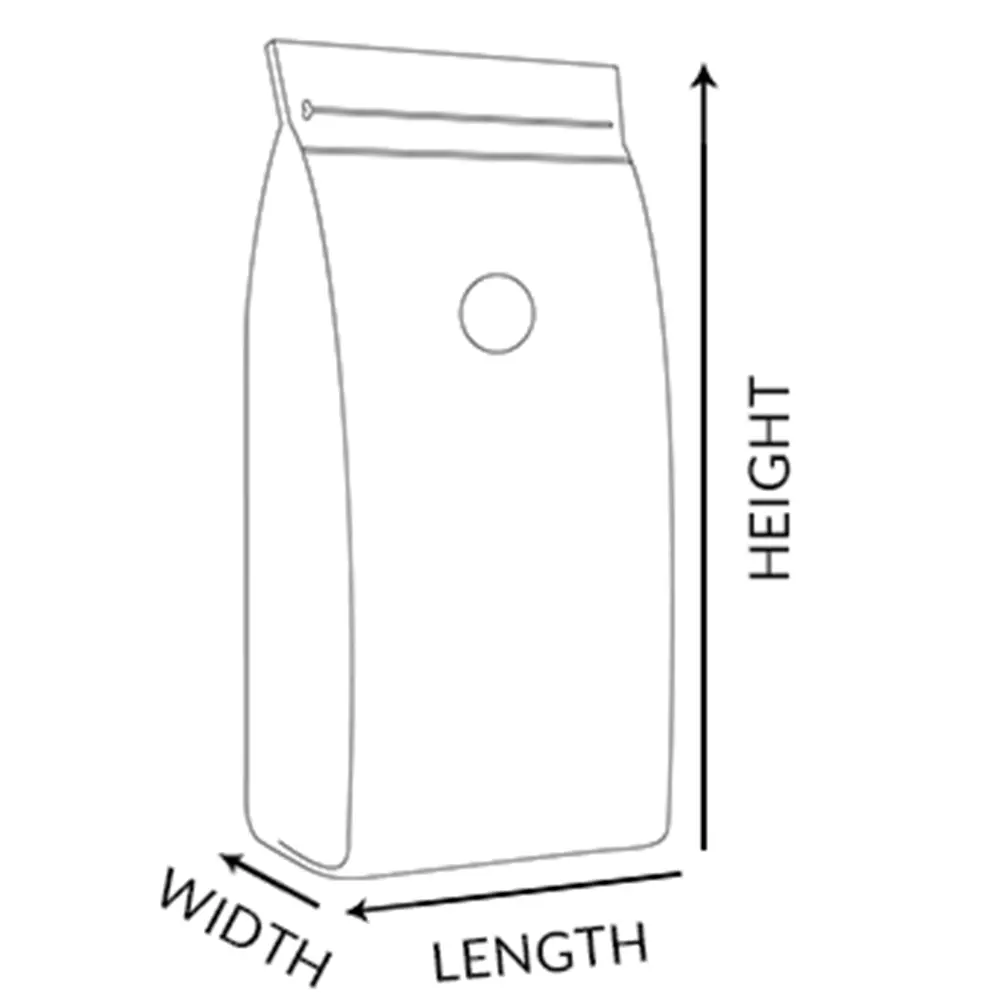

Flat bottom pouches come in several sizes. You can choose small, medium, or large pouches based on your product.

A small size is good for single servings. Medium and large sizes work well for bulk items.

Kaleadpack produce flat bottom pouches of different sizes and volumes to meet the needs of different markets and products.

| Volume (g) | Volume (oz) | Width (cm) | Width (in) | Length (cm) | Length (in) | Gusset (cm) | Gusset (in) |

|---|---|---|---|---|---|---|---|

| 100 | 4 | 9 | 3.5 | 18.5 | 7.3 | 5.5 | 2.2 |

| 250 | 8 | 9.5 | 3.7 | 23.8 | 9.4 | 6.5 | 2.6 |

| 500 | 16 | 11.5 | 4.5 | 26.5 | 10.4 | 7.5 | 3 |

| 750 | 24 | 13 | 5.1 | 30 | 11.8 | 8.5 | 3.3 |

| 1000 | 32 | 14 | 5.5 | 33 | 13 | 9.5 | 3.7 |

(The following table shows some typical sizes and volumes for flat bottom pouches, for reference only. The size and volume of a flat bottom pouch can vary based on the product and options you choose.)

Flat bottom pouches can be equipped with different closure options to provide convenience and functionality for the product. The most common closure options offered by KaleadPack for flat bottom pouches are:

Zipper offer a simple and safe method to open and close a bag, while also maintaining the product's freshness and quality. Zippers are available in many sizes, colors, and styles. Examples of zippers include single or double zippers, press-to-shut or slide-to-shut zippers, and conventional or ergonomic zippers.

Spout is a dispensing closure that consists of a plastic nozzle that can be attached to the pouch, either at the top, the side, or the corner. Spout provides an easy and precise way to pour, squeeze, or spray the product, as well as to prevent leakage or spillage. It can be customized with different sizes, shapes, and colors, as well as different caps, such as screw cap, flip cap, or push-pull cap. Using top spout in the pet treat industry is becoming popular.

Tin Tie is a flexible way to close flat bottom pouches. It is a thin metal tie covered in paper or plastic. Positioned at the pouch's top, it provides a simple and effective resealing method, ensuring product freshness.

We start with a detailed discussion to understand your packaging needs. This helps us define the specifications for your flat bottom pouches.

As soon as we have your requirements, we’ll work with your design to create a pouch that meets your needs. We can help you develop the design from scratch to completion, ensuring it aligns perfectly with your vision. We offer a wide selection of materials to suit your products, ensuring your pouch is both functional and vivid appealing.

Before full-scale production, we will produced a sample pouch. This allows you to see and feel the product, ensuring it meets your standards.

We value your feedback on the sample. We will make the necessary changes to the design or materials if adjustments are needed.

After the sample is approved, we begin full-scale production of your flat bottom pouches. Our advanced machinery ensures high-quality output.

High quality standards are ensured with strict quality checks on every pouch. This step is crucial to ensure you receive the best product possible.

As a final step, we package your pouches carefully and ship them in the right packaging to you. Our logistics department will ensure that your order arrives on time and in perfect condition, and we also provide EXW services.

We will review all your artwork designs and convert them into print-ready files. There are many technical considerations when printing barrier films, and we will handle all of these tasks for you. We will take your original artwork files and set them up for printing to ensure you get the best quality print, and develop digital art proofs that you can modify. KaleadPack focus on providing packaging that meets your requirements and budget.

There are two printing methods that KaleadPack offer, including:

| Digital Printing | Rotogravure Printing |

|---|---|

| Advantage: | Advantage: |

| No setup costs. | Lower per-unit cost than digital printing. |

| Shortest lead-times. | It is the most economical choice when scaling your business. |

| Great for start-ups and seasonal SKUS. | All Finish options are available. |

| Higher costs. | One-Time Plate costs. |

| Not advised for higher quantities. | Exceptional print durability and better ink opaqueness. |

| Limited finish options and printing effects. | |

| Unable to exact color match PMS colors and some other ink limitations. | |

| Shortcoming: | Shortcoming: |

| Higher costs. | One-Time Plate costs. |

| Not advised for higher quantities. | Exceptional print durability and better ink opaqueness. |

| Limited finish options and printing effects. | |

| Unable to exact color match PMS colors and some other ink limitations. | |

| MOQ : | MOQ : |

| 1000 | 10000 |

Matte and gloss finishes offer different looks and feels. Matte gives a smooth, non-shiny appearance. Gloss is shiny and reflective.

Plastic film is a thin and flexible material that can be transparent or opaque, depending on the type and thickness of the plastic. It provides good barrier, strength, and sealability properties for the product, as well as a smooth and glossy surface for printing. Plastic film can also be modified with additives or coatings to enhance its performance or appearance.

Aluminum foil is a thin and flexible sheet of aluminum that can provide a high barrier and strength properties for the product. Aluminum foil can provide excellent oxygen, light, and odor barrier, as well as good heat and moisture resistance.

Aluminum foil can also be printed with different colors and patterns to create a distinctive and attractive design. Aluminum foil can be used alone or laminated with other materials, such as plastic film or paper, to enhance its performance or appearance.

Kraft paper is a natural and biodegradable material that is made from wood pulp. Kraft paper can provide a rustic and eco-friendly appearance and feel for the product, as well as good printability and breathability.

Additives or coatings can also modify kraft paper to enhance its properties. Kraft paper can be used alone or laminated with other materials, such as plastic film or aluminum foil, to improve its barrier and strength properties.

Food and beverage pouches with flat bottoms are ideal for packaging a wide variety of items. The items include snacks, cereals, nuts, coffee, tea, spices, sauces, soups, juices, milk, yogurt, and cheese, etc. The pouch keeps the product fresh and flavorful by blocking out moisture, oxygen, light, and odors.

Flat bottom pouches are used for packaging garden and agricultural supplies such as seeds, fertilizers, and pesticides. Can protect the product from moisture, insects, rodents, and fungi, keeping it safe and effective.

A flat bottom pouch has a stable base. It stands upright on shelves. This design helps in displaying products better.

Custom pouches fit your brand needs. They can have your logo, colors, and designs. This makes your product stand out.

Yes, many are made with recyclable materials such as mono-pe and polylactic acid(PLA). This reduces waste and helps the environment.

Yes, flat bottom pouches have zip locks or sliders. This keeps the contents fresh after opening.

KaleadPack is a Chinese company that provides one-stop flexible packaging solutions, including flexible packaging bags, rollstock, and packaging machines. We specialize in offering high-quality certified packaging and support global shipping. Our products are versatile, customizable, and perfect for a range of industries, offering good prices and high quality.