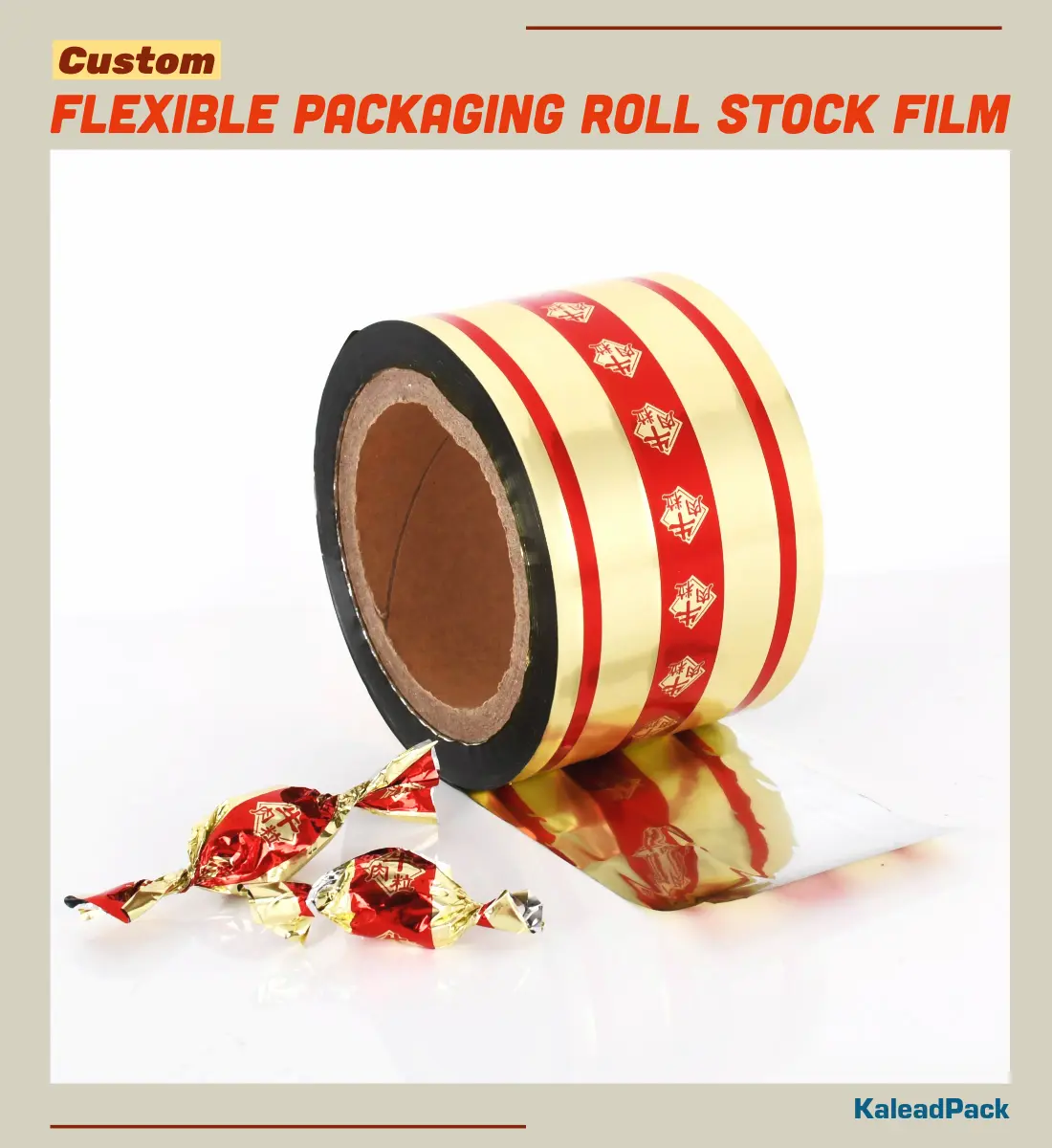

Roll Stock Film

KaleadPack provide cost-effective food grade custom printed roll stock film to meet your packing machine’s requirement, support global shipping.

Printed Roll Stock Film

Kalead Pack proudly presents our premium-quality Printed Roll Stock Film.

Designed to meet the diverse needs of businesses across various industries, our packaging solutions offer durability, versatility, and cost-effectiveness.

You can trust that every design element we made for you will be clear and precise. For flexible packaging roll stock film Kaleadpack can customize with:

- Matte or Glossy finishing

- Printing up to 10 colors

- Start MOQ with 300-500Kg by rotogravure print

- By digital print start from 1Kg, gravure print 300Kg

- BRC and ISO9001 Standard

Kalead Pack Custom Printed Roll Stock Film

Custom printed roll stock film is flexible packaging material. It is used for various products auto packing. You can see it in food, non-food items.

This film comes in rolls. Manufacturers use it to create packages of different shapes and sizes. It can be made of plastic, paper, or foil.

In the forming process, the packing machine shapes the film into a pouch or bag. Form-Fill-Seal (FFS) Machine heat the film to make it pliable. They mold it into the desired shape. The forming process is quick and efficient. It allows you to produce many packs in a short time that fit your production line.

Custom Your Roll Stock Film

Custom printed roll stock film offers many customization options. You can choose different materials based on your product needs. For example, Foil films offer barrier properties to consumable food or liquid against air and ultraviolet light.

You can also customize the design. Printing your brand’s by digital printing and rotogravure print.

Kalead Pack Custom printed roll stock film offers many features. includes:

Custom sizes: Match the exact dimensions you need.

Print designs: Add logos, text, images.

Barrier properties: Protect against moisture, oxygen, or light.

Material choices: Select from plastic, foil, or paper laminates.

Usage of Roll Stock Film Forming

Pillow Pouches

Pillow pouches are popular in packaging. They are ideal for snacks, candies, and dried foods. These pouches have a simple design. The film is folded over the product and sealed on three sides.

The Fin Seal and Lap Seal options ensure a secure closure. Fin Seal overlaps the edges, while Lap Seal aligns them side by side. Choose the best seal based on your product’s needs.

Twist Film

Cup Sealing

Custom Process of Roll Stock Film

After approval, the production timeline begins. Here’s a typical sequence:

-

Artwork Submission: Submit your design files.

-

Proof Review: Check and approve the proof.

-

Production Start: Manufacturing begins.

-

Quality Control: Inspect finished products.

-

Shipping: Factory pick-up and global delivery available.

Production timelines generally range from 1 to 4 weeks according to the order skus and quantity.

1. Initial Consultation

We start with a detailed discussion to understand your packaging needs. This helps us define the specifications for your roll stock.

2. Design and Material Selection

As soon as we have your requirements, we’ll work with your design to create a pouch that meets your needs. We can help you develop the design from scratch to completion, ensuring it aligns perfectly with your vision. We offer a wide selection of materials to suit your products, ensuring your pouch is both functional and vivid appealing.

3. Sample Production

Before full-scale production, we will produced few meters of roll stock and send the picture proof to you. This allows you to see the product printing and colors, ensuring it meets your standards.

4. Feedback and Adjustments

We value your feedback on the sample. We will make the necessary changes to the design or materials if adjustments are needed.

5. Full-Scale Production

After the pouch sample pack is approved, we begin full-scale production of your roll stock film. Our advanced machinery ensures high-quality output.

6. Quality Control

High quality standards are ensured with strict quality checks on every pouch. This step is crucial to ensure you receive the best product possible.

7. Packaging and Shipping

As a final step, we package your pouches carefully and ship them in the right packaging to you. Our logistics department will ensure that your order arrives on time and in perfect condition, and we also provide EXW services.

Artwork Process

We will review all your artwork designs and convert them into print-ready files. There are many technical considerations when printing barrier films, and we will handle all of these tasks for you. We will take your original artwork files and set them up for printing to ensure you get the best quality print, and develop digital art proofs that you can modify. KaleadPack focus on providing packaging that meets your requirements and budget.

Printing Method of Roll Stock

There are two printing methods that KaleadPack offer, including:

- Gravure Printing: involves engraving the image onto a cylinder. It is known for its high-quality print and is cost-effective for large runs but has higher setup costs for short runs.

- Digital Printing: doesn’t require printing plates, allowing for lower setup costs and making it ideal for short runs, variable data, and customization.

| Digital Printing | Rotogravure Printing |

|---|---|

| Advantage: | Advantage: |

| No setup costs. | Lower per-unit cost than digital printing. |

| Shortest lead-times. | It is the most economical choice when scaling your business. |

| Great for start-ups and seasonal SKUS. | All Finish options are available. |

| Higher costs. | One-Time Plate costs. |

| Not advised for higher quantities. | Exceptional print durability and better ink opaqueness. |

| Limited finish options and printing effects. | |

| Unable to exact color match PMS colors and some other ink limitations. | |

| Shortcoming: | Shortcoming: |

| Higher costs. | One-Time Plate costs. |

| Not advised for higher quantities. | Exceptional print durability and better ink opaqueness. |

| Limited finish options and printing effects. | |

| Unable to exact color match PMS colors and some other ink limitations. | |

| MOQ : | MOQ : |

| 1KG | 300KG |

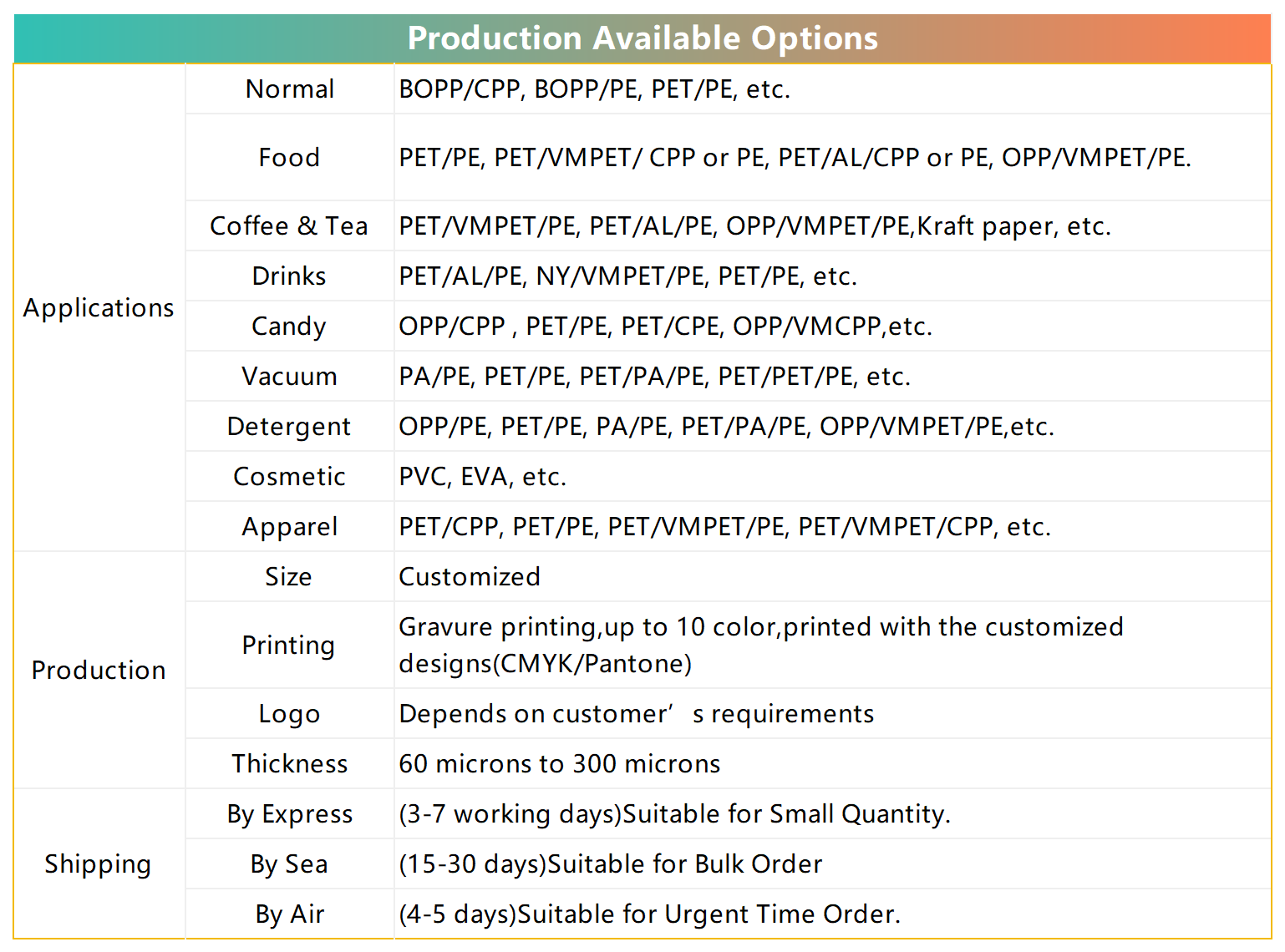

Custom Material

Choosing the right material is vital. Different products require different types of films. CPP film packaging, or cast polypropylene, is one option. It’s known for its clarity, strength, and flexibility.

Your choice of material affects the filling equipment used. Some films work better with specific machines.

Here are some common production available options for you to reference.

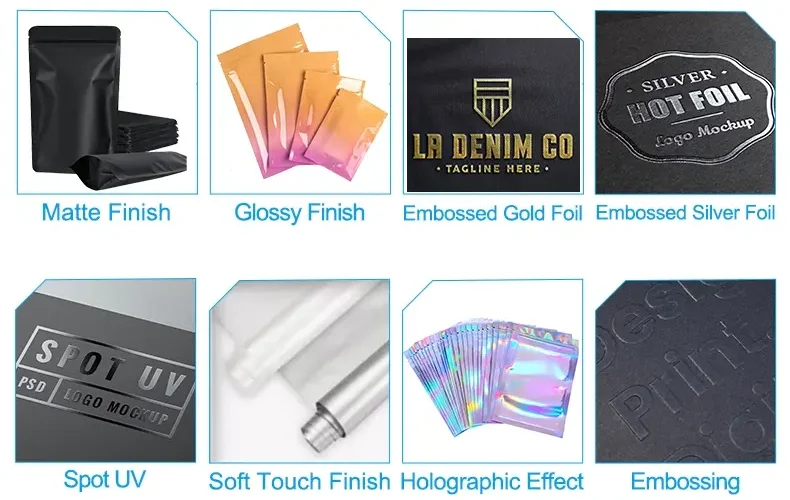

Finish Choices

Select finishes and coatings that suit your product. Matte finishes can give a premium look, while glossy finishes might be more eye-catching. Protective coatings can add durability and improve the feel of the packaging. These choices impact both appearance and functionality.

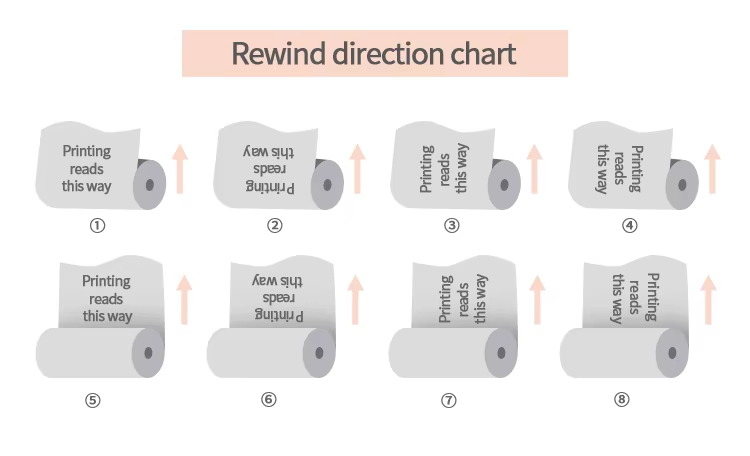

Rewind Direction

Rewind direction is crucial as it directly affects whether printed content is displayed correctly during use. The correct rewind direction ensures that the printed content unfolds in the machine or dispenser as intended.

-

Confirm Machine Requirements: Before use, confirm the specific rewind direction requirements of the machine and inform us of the desired direction based on the rewind direction chart before customizing the roll.

-

Check the Rewind Direction Chart: Choose the rewind direction that matches the machine’s requirements.

-

Testing: During test production, we will package the roll and conduct tests to ensure the printed content is displayed correctly.

Packaging Types

Food Packaging

Non-Food Packaging

Frequently Asked Questions

Why Choose Kalead Pack

KaleadPack is a Chinese company that provides one-stop flexible packaging solutions, including flexible packaging bags, rollstock, and packaging machines. We specialize in offering high-quality certified packaging and support global shipping. Our products are versatile, customizable, and perfect for a range of industries, offering good prices and high quality.