フラットボトムパウチ, also known as box pouches or flat bottom bag, are one of the most innovative and versatile packaging solutions in the market. These packaging are a combination of a stand-up pouch and a box. They offer convenience, can be eco-friendly, cost-effective, and have an attractive design. Many products use them, such as food, drinks, cleaning products, coffee, medicine, health, and gardening supplies.

This guide has everything you need to know about flat bottom pouches. It provides comprehensive information on flat bottom pouches, including details on their advantages, limitations, and industry uses. It also covers the materials, closures, sizes, and eco-friendly options available for these pouches.

Additionally, it discusses the manufacturing process, design validation, and packing machines used for flat bottom pouches. The guide also provides information on closure direction and answers frequently asked questions about these pouches.

At the end of this guide, you will have a complete understanding of flat bottom pouches. You will also learn how they can enhance the uniqueness of your product and increase customer satisfaction.

Advantages of Flat Bottom Pouches

Flat bottom pouches offer many advantages over traditional packaging, such as:

Convenience:

Flat bottom pouches are easy to open, close, fill, store, and transport. They have a spacious opening for easy access and a level base to stand upright on shelves or countertops. They also have gussets that expand when filled, creating more space for the product and reducing air inside the pouch. This helps to preserve the freshness and quality of the product and extend its shelf life.

Eco-friendly:

Flat bottom pouches are eco-friendly because they use lightweight materials, reducing waste and carbon emissions. They need less energy and resources for production and transportation compared to glass jars, metal cans, or plastic bottles. The pouches are smaller in landfills and can be recycled or composted based on what they are made of. According to a study by the Flexible Packaging Association, switching from rigid containers to flexible pouches can save up to 75% of packaging weight, 52% of greenhouse gas emissions, and 55% of energy consumption.

Cost-effectiveness:

Flat bottom pouches are more economical than rigid containers, as they lower the production, transportation, and storage costs. These pouches require fewer resources and equipment to make. They can also have high-quality printing images and tags directly on the pouch. They also reduce shipping and storage costs because they are lighter and smaller than rigid containers. Additionally, they can be shipped flat before filling, offering a higher product-to-package ratio, reducing waste, and increasing profit.

Potential for attractive design:

The flat bottom pouch has five panels that can be customized with colors, shapes, logos, images, and information, allowing for the creation of a unique and attractive design. They can also be enhanced with various features, such as windows, zippers, spouts, handles, or valves, to add functionality and convenience to the pouch. They are more adaptable and versatile than inflexible containers, making them suitable for different products and markets.

Considerations of Flat Bottom Pouches

Recycling Considerations:

While flat bottom pouches often consist of various materials for strength and protection, some recycling facilities may require specialized processing. To make things easier, there's a positive trend in developing pouches that are designed to be easily recyclable or even biodegradable.

Transit Resilience:

Like any packaging, flat bottom pouches benefit from careful handling during transit to ensure product safety. Taking a little extra care in packing can go a long way in preventing any potential issues during transportation.

Storage Practicality:

Flat bottom pouches are great for smaller to medium quantities of items. For larger quantities, a combination with other packaging types or incorporating user-friendly features can optimize storage.

Tamper Evidence and Child Resistance:

Ensuring product safety is always a priority. While it might be a bit more nuanced than with rigid containers, flat bottom pouches can still be equipped with effective tamper-evident and child-resistant features.

Consumer Perception:

We understand the importance of how your product is perceived. To address any concerns, we offer flat bottom pouches in high-quality materials and finishes, providing a touch of elegance and luxury.

Industry Applications

食品・飲料:

Flat bottom pouches are ideal for packaging food and beverage products, such as snacks, cereals, grains, nuts, seeds, dried fruits, coffee, tea, spices, herbs, sauces, soups, juices, milk, yogurt, cheese, and more. The pouch can preserve the flavor, aroma, freshness, and nutrition of the product and prevent moisture, oxygen, light, and odor from entering or escaping the pouch.

Some examples of food and beverage products that use flat bottom pouches are:

- Kraft paper flat bottom pouches for coffee beans, tea leaves, or spices, with a zipper, a valve, and a window.

- Metallized film flat bottom pouches for snacks, cereals, or nuts, with a zipper and a tear notch.

- Aluminum foil flat bottom pouches for sauces, soups, or juices, with a spout and a handle.

家庭用品・パーソナルケア:

Flat pouches are ideal for packaging household and personal care items, including detergents, cleaners, wipes, shampoos, conditioners, lotions, creams, gels, masks, makeup, and more. They can protect the product from contamination, leakage, or evaporation and maintain its quality and efficacy.

Some examples of home and personal care products that use flat bottom pouches are:

- Plastic film flat bottom pouches for detergents, cleaners, or wipes, with a zipper and a window.

- Metallized film flat bottom pouches for shampoos, conditioners, or lotions, with a spout and a cap.

- Aluminum foil flat bottom pouches for creams, gels, or masks, with a zipper and a tear notch.

工業・自動車:

Flat bottom pouches can be used for packaging industrial and automotive products, such as paints, coatings, adhesives, sealants, lubricants, oils, greases, solvents, and more. They can withstand high temperatures, pressures, and chemicals and prevent the product from spilling, exploding, or corroding. They can also be easy to pour, mix, or apply, depending on the product and the material.

Some examples of industrial and automotive products that use flat bottom pouches are:

- Plastic film flat bottom pouches for paints or adhesives, with a spout and a cap.

- Metallized film flat bottom pouches for sealants, lubricants, or oils, with a valve and a handle.

- Aluminum foil flat bottom pouches for solvents, greases, or acids, with a spout and a cap.

医薬品・医療:

Flat bottom pouches are suitable for packaging pharmaceuticals and healthcare products, including pills, capsules, tablets, powders, liquids, syrups, sprays, creams, and ointments. They protect the product from moisture, oxygen, light, and bacteria, ensuring its safety and effectiveness. They can also be tamper-evident, child-resistant, or sterile, depending on the product and the material.

Some examples of pharmaceuticals and healthcare products that use flat bottom pouches are:

- Plastic film flat bottom pouches for pills, capsules, or tablets, with a zipper and a tear notch.

- Metallized film flat bottom pouches for powders, liquids, or syrups, with a spout and a cap.

- Aluminum foil flat bottom pouches for sprays, creams, or ointments, with a nozzle and a cap.

園芸・農業資材:

Flat bottom pouches can also be employed for packaging garden and agricultural supplies, such as seeds, fertilizers, pesticides, herbicides, fungicides, and more. They can protect the product from moisture, insects, rodents, and fungi and preserve its viability and effectiveness. They can also be easy to store, transport, and use, depending on the product and the material.

Some examples of garden and agricultural supplies that use flat bottom pouches are:

- Kraft paper flat bottom pouches for seeds, with a zipper and a window.

- Plastic film flat bottom pouches for fertilizers, with a zipper and a tear notch.

- Metallized film flat bottom pouches for pesticides, herbicides, or fungicides, with a spout and a cap.

Common Material Structures for Flat Bottom Pouches

Plastic film:

プラスチックフィルムは薄く柔軟な素材で、プラスチックの種類や厚さに応じて透明または不透明になります。製品に対して優れたバリア性、強度、シール性を提供するほか、印刷用の滑らかで光沢のある表面を有します。プラスチックフィルムは添加剤やコーティングで改質し、性能や外観を向上させることも可能です。

Some examples of plastic film used in flat bottom pouches are:

- Polyethylene (PE): PE is a widely used plastic film that is cheap, durable, and recyclable. PE can provide good moisture and chemical resistance, as well as good sealability and flexibility. It can be blended with other polymers or additives to improve its properties. PE can be classified into different grades, such as low-density (LDPE), linear low-density (LLDPE), medium-density (MDPE), high-density (HDPE), or ultra-high molecular weight (UHMWPE), depending on its density and molecular weight.

- Polypropylene (PP): PP is another common plastic film that is strong, lightweight, and heat-resistant. PP can provide good oxygen and light barrier, as well as good stiffness and clarity. It can be modified with additives or coatings to enhance its properties. PP can be classified into different types, such as homopolymer (HPP), random copolymer (RPP), or impact copolymer (IPP), depending on its composition and structure.

- Polyester (PET): PET is a high-performance plastic film that is clear, strong, and stable. PET can provide excellent oxygen and light barrier, as well as good heat and chemical resistance. It can be modified with additives or coatings to enhance its properties. PET can be classified into different grades, such as amorphous (APET), crystalline (CPET), or oriented (OPET), depending on its crystallinity and orientation.

- Polyamide (PA): PA, also known as nylon, is a tough and flexible plastic film that can provide good oxygen and aroma barrier, as well as good puncture and abrasion resistance. PA can be modified with additives or coatings to enhance its properties. PA can be classified into different types, such as nylon 6, nylon 66, or nylon 12, depending on its molecular structure and the number of carbon atoms.

- Polylactic acid (PLA): PLA is a biodegradable and compostable plastic film made from renewable resources, such as corn starch or sugar cane. PLA can provide good clarity and gloss, as well as good stiffness and strength. It can be modified with additives or coatings to enhance its properties. PLA can be classified into different types, such as PLA 2000D, PLA 3000D, or PLA 4000D, depending on its molecular weight and viscosity.

Metallized film:

Metallized film is a plastic film that is coated with a thin layer of metal, such as aluminum, silver, or copper, to provide a metallic appearance and improve its barrier and strength properties. Metallized film can provide excellent oxygen, light, and odor barrier, as well as good heat and moisture resistance.

Metallized film can also be printed with different colors and patterns to create a distinctive and attractive design. Metallized film can be made from different types of plastic film, such as PE, PP, PET, or PA, depending on the product and the application.

Aluminum foil:

アルミニウム箔は薄いアルミシートで、高いバリア性と強度を付与。酸素・光・臭いを遮断し、耐熱性・防湿性に優れる。

多色印刷や模様付けで独自デザインが可能。単体使用の他、プラスチックフィルムや紙とのラミネートで性能/外観を向上。

Kraft paper:

木材パルプ製の自然分解可能な素材。素朴でエコな風合いと良好な印刷適性・通気性を兼備。

クラフト紙は添加物やコーティングを施すことで特性を向上させることが可能です。単独で使用するほか、プラスチックフィルムやアルミ箔など他の材料とラミネート加工することで、バリア性や強度を高めることができます。

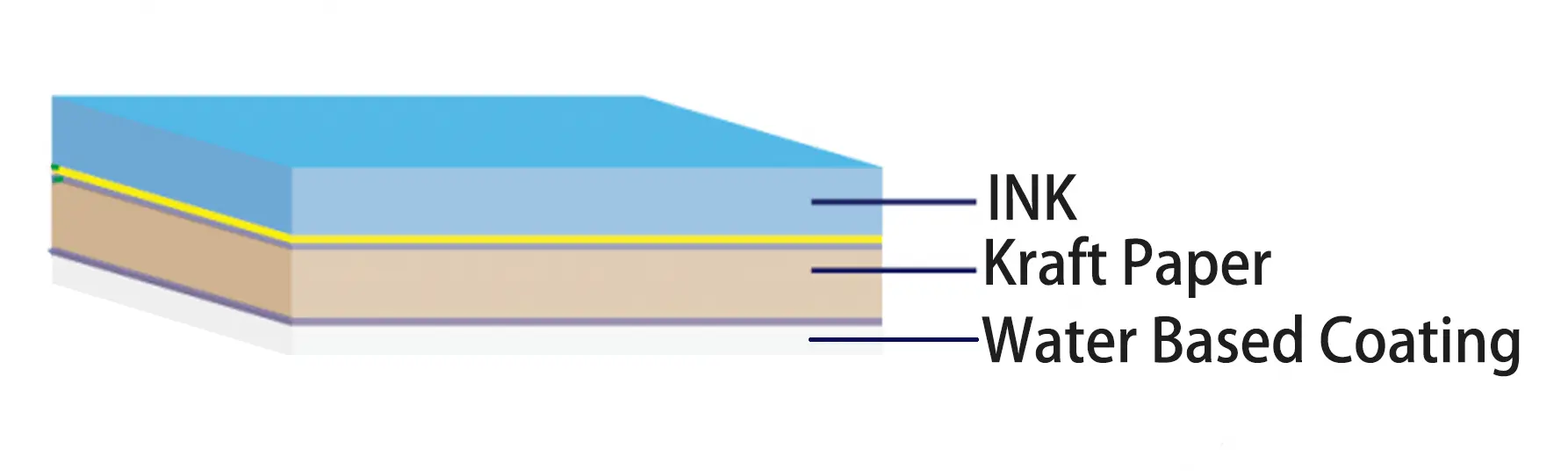

Water-based coatings:

It’s an eco-friendly surface treatment for flat bottom pouch, involve applying a protective layer with water as the primary solvent. Unlike traditional coatings, they reduce environmental impact by minimizing volatile organic compound (VOC) emissions, making them safe and suitable for various materials. The coatings offer quick drying options, good physical properties, and versatile aesthetics through color and texture variations. While they have slower drying times and are affected by environmental conditions, their application in the packaging industry is expanding due to increasing environmental regulations and advancements in technology.

If you're looking to explore the full potential of eco-friendly options for your packaging needs, We highly recommend reaching out to industry professionals and packaging experts. These specialists possess in-depth knowledge of the latest materials and technologies and can provide tailored advice to ensure that your packaging not only looks great but also aligns with the best environmental practices for your packaging pouches. Please feel free to お問い合わせ.

How to Manufacture Flat Bottom Pouch?

There are several printing methods that can be used on Flat bottom pouch, including:

グラビア印刷: This method involves engraving the image onto a cylinder. It is known for its high-quality print and is cost-effective for large runs but has higher setup costs for short runs.

デジタル印刷: This method doesn't require plates, allowing for lower setup costs and making it ideal for short runs, variable data, and customization.

Flexographic Printing: This is a direct printing method using flexible photopolymer printing plates wrapped around rotating cylinders. It's commonly used for flexible materials and is suited for medium to long print runs.

The choice of printing method will depend on the run length, the complexity of the design, the number of colors, and costs.

1. Gravure Printing:

Design: The first step is designing the pouch, which includes the artwork, dimensions, and the placement of the spout. This is usually done using computer-aided design (CAD) software.

Plate Making:Plate making is an important step before printing. It turns the digital design of the pouch into physical printing plates or engraved cylinders. These plates are carefully made to match the colors and details of the artwork, ensuring accurate reproduction during printing.

Material Selection: Flat Bottom Pouches are made from multiple layers of barrier materials that can include a combination of polyethylene (PE), polypropylene (PP), polyester (PET), nylon, aluminum foil, and other materials. These materials are chosen based on the requirements of the product to be packaged, such as moisture, oxygen barrier, strength, flexibility, and food safety.

Printing: Using the design, the outer layer of the pouch is printed with brand-specific graphics. This is typically done via rotogravure or flexographic printing. Specialized printing inks are used to ensure the prints are food-safe and durable.

Lamination: After printing, the outer layer is laminated with the inner layers to create a composite structure. This is achieved using a lamination adhesive and a lamination machine that applies heat and pressure to bond the layers together into a single sheet.

Curing: The laminated material needs to cure for a specific time to ensure proper adhesion and set of the laminating adhesive.

Slitting: The cured, laminated material is then slit into smaller rolls that match the width required for the final pouch size.

Pouch Formation: The material is formed into pouches using a pouch-making machine. This involves cutting the material and then sealing it on three sides (back, bottom, and one of the top sides), leaving one side open for the spout.

Quality Control: The finished spout pouches undergo quality control checks. This can include tests for leaks, seal integrity, spout function, and overall quality of printing and lamination.

2. Digital Printing

Design: The first step is same as the gravure printing, designing the pouch, which includes the artwork, dimensions, and the placement of the spout. This is usually done using computer-aided design (CAD) software.

Prepress: After the artwork is finished, a prepress technician prepares the digital files for printing. This stage involves changing color settings, checking the resolution for printing, and arranging images if multiple designs are printed together.

RIP (Raster Image Processor): Artwork files are sent to a RIP, software that converts images into a format the digital printer can understand and process. During this stage, the data is rasterized, meaning it is broken down into printable dots.

Printing: The digital printer applies ink directly to the packaging material without the use of traditional printing plates. UV or solvent-based inks typically cure or dry instantaneously. Digital printers can handle a wide array of materials and can print complex, high-resolution, full-color images with precision.

Curing or Drying: When the ink is placed on the substrate (the packaging material), it undergoes a curing process using ultraviolet light or a rapid solvent evaporation method, contingent on the kind of ink utilized. This step ensures the ink adheres properly to the material and is immediately ready for the next stage.

Lamination: To make the flat bottom pouch stronger and more durable, a lamination process can be used. This process involves adding a clear protective layer over the printed material. This layer protects the ink and improves the appearance of the print.

Converting: The material is cut and given extra features like spouts, tear notches, and hang holes. This step shapes the printed material into finished pouches.

Quality Control: The finished flat bottom pouches undergo quality control checks. This can include tests for leaks, seal integrity, spout function, and overall quality of printing and lamination.

Image source: HP Indigo 200K Digital Press

3.Flexographic Printing:

Design and Plate Creation: The process begins with crafting the visual design for the spout pouch, which includes logos, product information, and decorative elements. The design is broken down by color, and for each color, a flexible printing plate is made, which will press the design onto the material.

Inks and Color Preparation: The inks used in flexo printing can vary, including solvent-based, water-based, or UV-curable options. Colors are prepared to match the design specifications, employing systems like Pantone for accuracy. An anilox roll applies a precise quantity of ink to the printing plate. It features tiny cells that control the amount of ink distributed.

Press Setup: Plates for each color are installed on the rolling cylinders within the flexographic press. Individual color stations have an anilox roll to meter the right amount of ink onto the printing plate. The alignment of colors, or registration, is finely adjusted so the final image is printed correctly.

Preparing the Base Materials: The substrate, typically a plastic film for spout pouches, is loaded into the press. The tension of the material is adjusted to avoid any stretching or wrinkling that could compromise the quality of the print.

The Printing Process: As the material moves through the press, the colors are applied sequentially at high speed. After each color application, the ink is quickly dried using hot air or UV light to avoid smudging and to prepare for the next layer of ink.

Post-Printing Steps: The printed substrate is inspected for any defects, often with the help of specialized lighting and camera systems. If a spout pouch requires additional layers for protection, lamination occurs, combining the printed layer with another material layer.

Pouch Formation and Completion: The printed and optionally laminated material is then cut and shaped into pouches with the edges sealed, except where the spout will be positioned. The spout is attached at a stage determined by the manufacturing process, which may be before or after the pouch is filled. Finally, the pouches are filled with the product, and the final seal is applied above the spout, finalizing the product.

Quality Control: The finished spout pouches undergo quality control checks. This can include tests for leaks, seal integrity, spout function, and overall quality of printing and lamination.

4. What is the different between Digital Printing and Plate Printing?

デジタル印刷: Digital printing is the process of printing digital-based images directly onto your package. Artwork is separated into four ink colors: cyan, magenta, yellow, and black (CMYK+W). This type of printing is best for small runs or situations with a lot of different designs. However, some advanced coatings and techniques (Spot UV, Spot Matte) are not possible with digital printing.

Plate Printing: Plate printing is commercial printing where the design of your pouch is separated into multiple color plates. Plate printing yields the lowest per-unit costs available. Brands you see in Walmart, Target, and so forth generally use plate printing. Most jobs can be completed with three to six plates, and the use of metallic color may require additional plates. Up to 10 colors can be used.

| デジタル印刷 | Plate Printing | ||

|---|---|---|---|

| 利点: | 利点: | ||

| 初期費用不要。 | デジタル印刷より単価が安い。 | ||

| 最短リードタイム。 | 事業拡大時にもっとも経済的な選択肢。 | ||

| スタートアップ企業や季節限定SKUに最適。 | 全仕上げオプション対応可能。 | ||

| コストが高い。 | 版作成の一時費用が発生。 | ||

| 大量生産には非推奨。 | 卓越した印刷耐久性とインクの高い不透明度。 | ||

| 仕上げオプションと印刷効果に制限あり。 | |||

| PMSカラー完全再現不可・その他インクの制約。 | |||

| 短所: | 短所: | ||

| コストが高い。 | 版作成の一時費用が発生。 | ||

| 大量生産には非推奨。 | 卓越した印刷耐久性とインクの高い不透明度。 | ||

| 仕上げオプションと印刷効果に制限あり。 | |||

| PMSカラー完全再現不可・その他インクの制約。 |

一般的な閉じ方オプション

Flat bottom pouches can be equipped with different closure options to provide convenience and functionality for the product. The most common closure options offered by Kalead Pack for flat bottom pouches are:

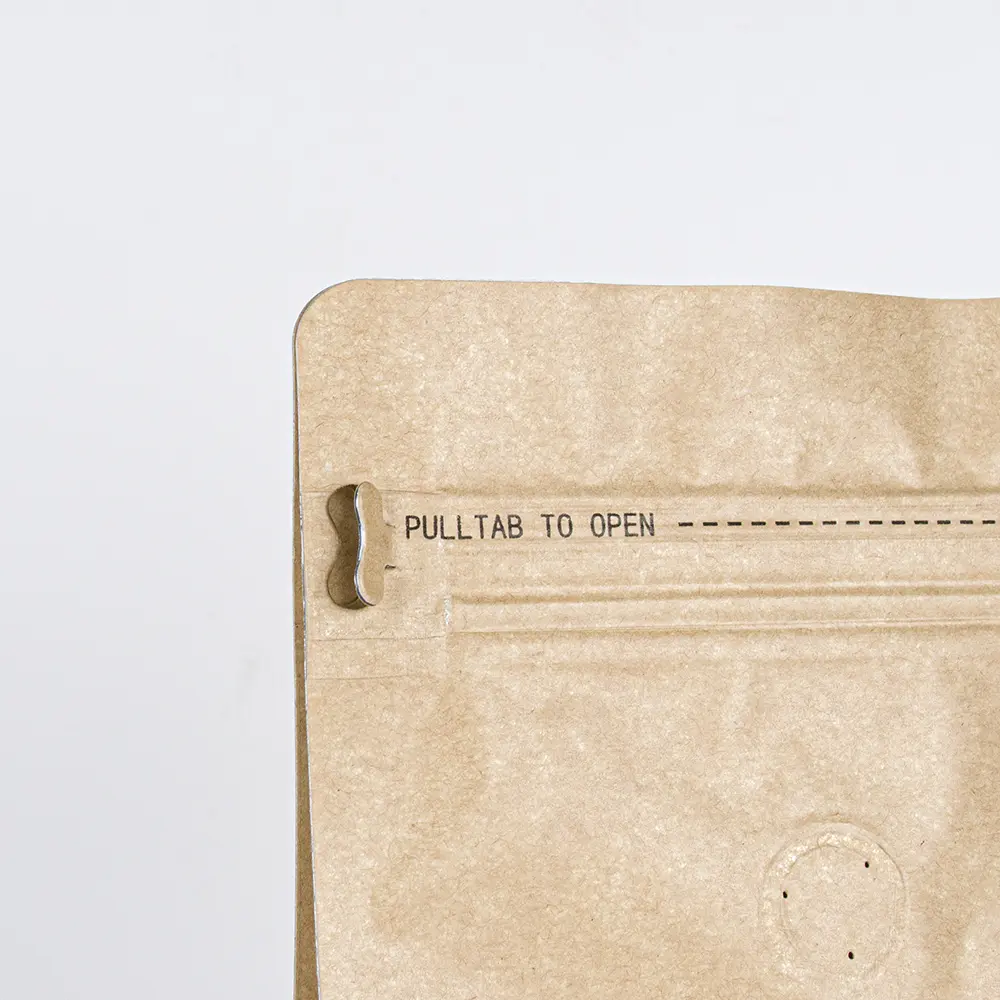

Zipper:

Zipper is a resealable closure that consists of two interlocking plastic or metal teeth that can be opened and closed by sliding a tab along the track. Zipper provides an easy and secure way to open and close the pouch, as well as to preserve the freshness and quality of the product. It can be customized with different sizes, colors, and designs, such as single or double zipper, press-to-close or slide-to-close zipper, or standard or ergonomic zipper.

Spout:

Spout is a dispensing closure that consists of a plastic or metal nozzle that can be attached to the pouch, either at the top, the side, or the corner. Spout provides an easy and precise way to pour, squeeze, or spray the product, as well as to prevent leakage or spillage. It can be customized with different sizes, shapes, and colors, as well as different caps, such as screw cap, flip cap, or push-pull cap. Using top spout in the pet treat industry is becoming popular.

(To protect customer privacy, the brand name has been blurred.)

Tin Tie:

Tin Tie is a versatile closure option for flat bottom pouches, featuring a thin metal tie encased in paper or plastic. Positioned at the pouch's top, it provides a simple and effective resealing method, ensuring product freshness. Kalead Pack offers customization in length, color, and design, catering to branding needs. Popular for coffee and snacks, Tin Tie is user-friendly, requiring no tools for resealing, and supports sustainability by facilitating easy pouch separation for recycling, making it an excellent choice for diverse packaging applications.

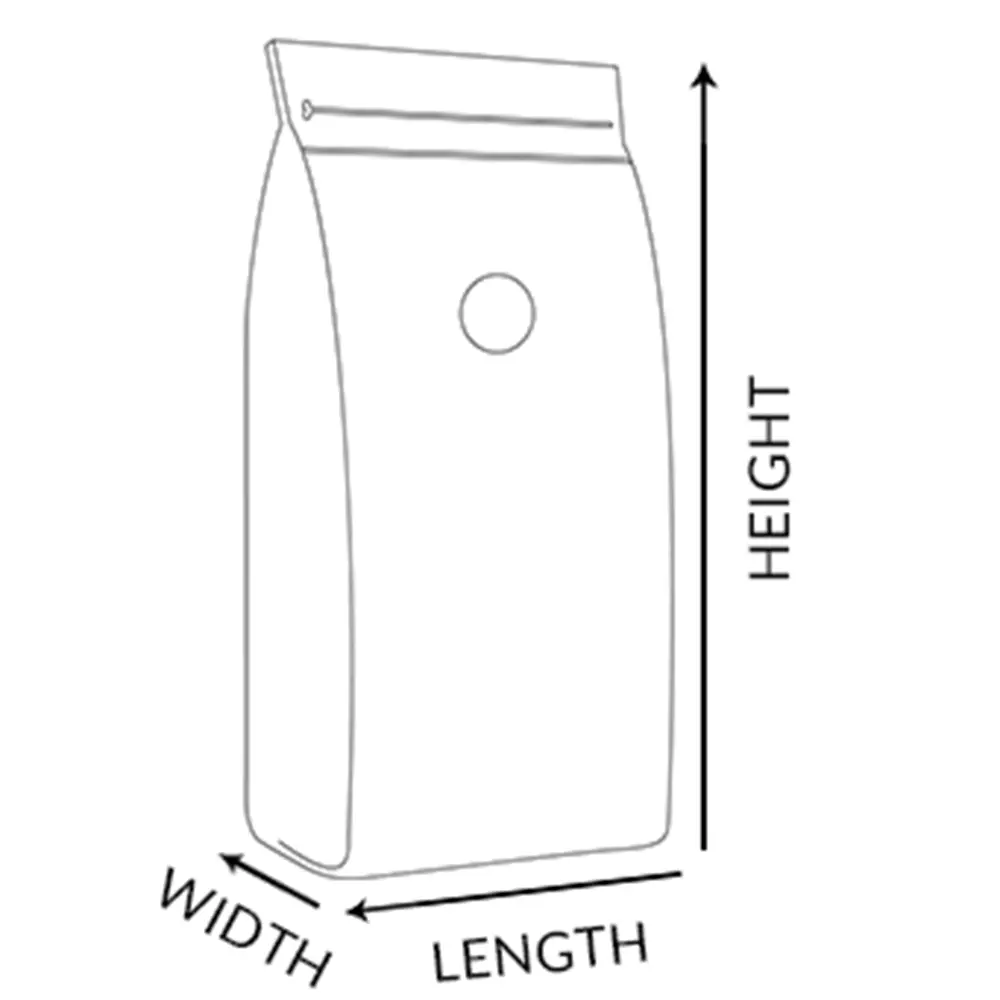

Common Sizes and Volumes for Flat Bottom Pouches

Flat bottom pouches can be made in different sizes and volumes to accommodate different products and markets. The size and volume of a flat bottom pouch can be measured in milliliters (ml), ounces (oz), centimeters (cm), or inches (in), depending on the preference and the standard. The size and volume of a flat bottom pouch can also be affected by the material, the shape, and the filling of the pouch.

The following table shows some typical sizes and volumes for flat bottom pouches, for reference only. The actual size and volume of a flat bottom pouch may vary depending on the specific product and the functional options that you need.| Volume (ml) | 容量(oz) | 幅(cm) | 幅(in) | 長さ(cm) | 長さ(in) | ガセット(cm) | ガセット(in) |

|---|---|---|---|---|---|---|---|

| 100 | 4 | 9 | 3.5 | 18.5 | 7.3 | 5.5 | 2.2 |

| 250 | 8 | 9.5 | 3.7 | 23.8 | 9.4 | 6.5 | 2.6 |

| 500 | 16 | 11.5 | 4.5 | 26.5 | 10.4 | 7.5 | 3 |

| 750 | 24 | 13 | 5.1 | 30 | 11.8 | 8.5 | 3.3 |

| 1000 | 32 | 14 | 5.5 | 33 | 13 | 9.5 | 3.7 |

How to Validate that the Pouch Design is Right for You?

Before finalizing a flat bottom pouch order, it is important to validate that the pouch design is right for you and your product. To do this, you can:

Get Prototypes:

Get sample flat bottom pouches made to your specs for testing quality, performance, and appearance. Use them to fix any issues, gather feedback, and get necessary approvals. Prototypes can be obtained from manufacturers or suppliers for free or a fee, depending on quantity and complexity.

Run Tests:

Run experiments to measure pouch characteristics like barrier strength and sealability. These tests help verify suitability and improve pouch performance. You can conduct tests in-house or hire a third-party lab, depending on equipment and cost considerations. Additionally, samples are often used to assess the printed size and ensure it meets expectations. While samples have a lower tolerance for testing compared to final products, they are crucial for evaluating print quality and alignment.

Request Revisions:

Ask for changes to pouch design based on feedback from prototypes and tests. Revisions aim to achieve an optimal design that meets customer expectations. Manufacturers or suppliers may accommodate revision requests, with costs varying based on the extent of changes.

Closure Direction for Flat Bottom Pouches

Flat bottom pouches can have different closure directions, depending on the placement and the orientation of the closure system, such as the zipper, the spout, or the valve, on the pouch. The closure direction can affect the appearance, the functionality, and the convenience of the pouches, as well as the consumer preference and behavior. The most common closure directions for flat bottom pouches are:

- Top closure: Top closure is when the closure system is located at the top of the pouch, parallel to the width of the pouch. Top closure can provide a wide and easy opening and closing of the pouch, as well as good visibility and accessibility of the product. Top closure can also allow the pouch to be hung or displayed vertically, as well as to be stored horizontally or vertically. Top closure is suitable for products that are solid, granular, or powdered, such as snacks, cereals, or coffee.

- Top-side closure: Top-side closure is when the closure system is located at the top of the pouch, perpendicular to the width of the pouch. Top-side closure can provide a narrow and precise opening and closing of the pouch, as well as good control and accuracy of the product. Top-side closure can also allow the pouch to be hung or displayed horizontally, as well as to be stored horizontally or vertically. Top-side closure is suitable for products that are liquid, viscous, or gel-like, such as sauces, soups, or shampoos.

- Bottom closure: Bottom closure is when the closure system is located at the bottom of the pouch, parallel to the width of the pouch. Bottom closure can provide a convenient and secure way to seal the pouch after filling the product. Bottom closure can also allow the pouch to be stored horizontally or vertically but not hung or displayed. Bottom closure is suitable for products that are heavy, bulky, or irregular, such as pet food, rice, or nuts.

- Bottom-side closure: Bottom-side closure is when the closure system is located at the bottom of the pouch, perpendicular to the width of the pouch. Bottom-side closure can provide a flexible and versatile way to dispense the product from the pouch. Bottom-side closure can also allow the pouch to be stored horizontally or vertically but not hung or displayed. Bottom-side closure is suitable for products that are liquid, viscous, or gel-like, such as beverages, detergents, or lotions.

- Side closure: Side closure is when the closure system is located on one of the side gussets of the pouch, parallel to the length of the pouch. Side closure can provide a unique and distinctive way to open and close the pouch, as well as to show the product. Side closure can also allow the pouch to be hung or displayed vertically, as well as to be stored horizontally or vertically. Side closure is suitable for products that are solid, granular, or powdered, such as candy, spices, or tea.

Suitable Packing Machines for Filling Flat Bottom Pouches

Flat bottom pouches can be filled with different packing machines, depending on the type, quantity, and speed of the product and the pouches. The most suitable packing machines for filling flat bottom pouches are:

- Rotary Premade Bag Packing Machine: The Rotary Premade Bag Packing Machine is an advanced packaging solution that efficiently handles pre-made pouches. The product is filled into pre-made pouches using a machine. The filling process can be done either manually or automatically. This cutting-edge machine ensures a high-quality and efficient packing process, offering exceptional flexibility and versatility in pouch design and accommodated product types.

- Collar Type Packing Machine: The Collar Type Packing Machine represents a dynamic packaging solution using rollstock film that is not pre-formed or printed. This machine continuously or intermittently forms, fills, and seals pouches with the product. Offering a cost-effective and high-speed packing process, the Collar Type Packing Machine ensures consistency and reliability in both pouch quality and product quantity.

Equipped with various features such as weighing, filling, sealing, coding, or labeling, the Rotary Premade Bag Packing Machine enhances overall functionality and convenience. Works well for small to medium-sized production of flat bottom pouches, striking a balance between affordable setup and efficient operation.

Customizable features include forming, filling, sealing, cutting, coding, or labeling, contributing to heightened performance and efficiency. Ideal for large-scale production of flat bottom pouches, the Collar Type Packing Machine is characterized by a higher initial cost but compensates with remarkable speed and productivity.

Frequently Asked Questions about Flat Bottom Pouches

Here are some of the frequently asked questions and answers about flat bottom pouches, for your reference:

| Question | Answer |

|---|---|

| What is the minimum order quantity for flat bottom pouches? | The minimum order quantity for flat bottom pouches depends on the manufacturer or the supplier, as well as the design, the material, and the size of the pouches. Generally, the minimum order quantity for flat bottom pouches in gravure printing ranges from 10,000 to 50,000 pieces, digital printing from 1000 pieces, depending on the printing method and the pouch sizes. |

| How can I order samples of flat bottom pouches? | Flat bottom pouch samples can be procured from the manufacturer or distributor, either digitally or physically, subject to their service terms and policies. Choose from their available flat bottom pouches or request custom pouches designed for your specific requirements. There might be a charge for the samples, in addition to shipping and handling expenses, contingent on the number and intricacy of the pouches. There might also be a waiting period, contingent on the pouches' availability and delivery schedule. |

| How can I choose the best material for my flat bottom pouches? | 平底袋に最適な材料は、バリア性、強度、シール性、耐久性、機能性、互換性、外観、コスト、環境影響などの特性と、お客様の製品及び市場の要件に基づいて選択できます。平底袋の一般的な材料構造を参照いただくか、当社にご相談いただければ、最適な材料選定のガイダンスとアドバイスを提供いたします。 |

結論

平底袋は市場で最も革新的かつ多用途な包装ソリューションの一つです。様々な製品や業界において、利便性、環境配慮、コスト効率、目を引くデザインを実現します。材料、閉口方式、サイズ・容量、エコフレンドリーオプション、製造方法、デザイン承認、包装機械、閉口方向など、顧客と市場のニーズに応じて多様なカスタマイズが可能です。

平底袋にご興味をお持ちの方やご質問がございましたら、Kalead Packまでお気軽にお問い合わせください。当社は平底袋をはじめ、スポーツ袋、スタンドアップ袋、サイドガゼット袋など、柔軟な包装ソリューションの専門メーカー・サプライヤーです。高品質なカスタム平底袋の提供に加え、無料サンプル、競争力ある価格、迅速な納期、優れたサービスを約束します。皆様からのご連絡を心待ちにしております。

お探しの情報が見つからない場合は、下記の 「お問い合わせ」 をクリックください。お問い合わせや見積り依頼に対して、24時間以内にご返信いたします。関連製品: