Pillow Pouch Bag

Pillow Pouch Bag is a economical, easy-to-fill packaging solution for candies, nuts, granola, and various other products. They shine on shelves with their wrap-around graphics, distinctive film choices, and consumer-friendly attributes, making them not only a practical but also an attractive packaging option.

Kalead Pack Custom Pillow Pouch Bag

Pillow Pouch Bags are a popular type of flexible packaging known for their simple and economical design. They are named for their resemblance to a pillow once filled, ballooning in the center and flattening out at the top and bottom seals.

Pillow Pouch Bags are an economical, easy-to-fill packaging solution for candies, nuts, granola, and various other products.

These packaging options have an eye-catching design, special movie choices, and easy-to-use features. They stand out on store shelves because of this. Therefore, they are both practical and attractive.

Customise Your Pillow Pouch Bag

Pillow pouch bags can be customized for your products and brand styles. Here are some of the key customization options:

| Specification | Details |

|---|---|

| MOQ | 10000 Pcs By Rotogravure Printing |

| Size | 50×70mm (Min) 350×600mm (Max) |

| Material | BOPP/PET + PET/PETAL/Kraft Paper/ + LLDPE/CPP + Customize |

| Thickness | 50 Microns - 120 Microns (2 Mil - 5 Mil) |

| Function | Punch Hole, Handle, Metallized, Fin Seal/Lap Seal |

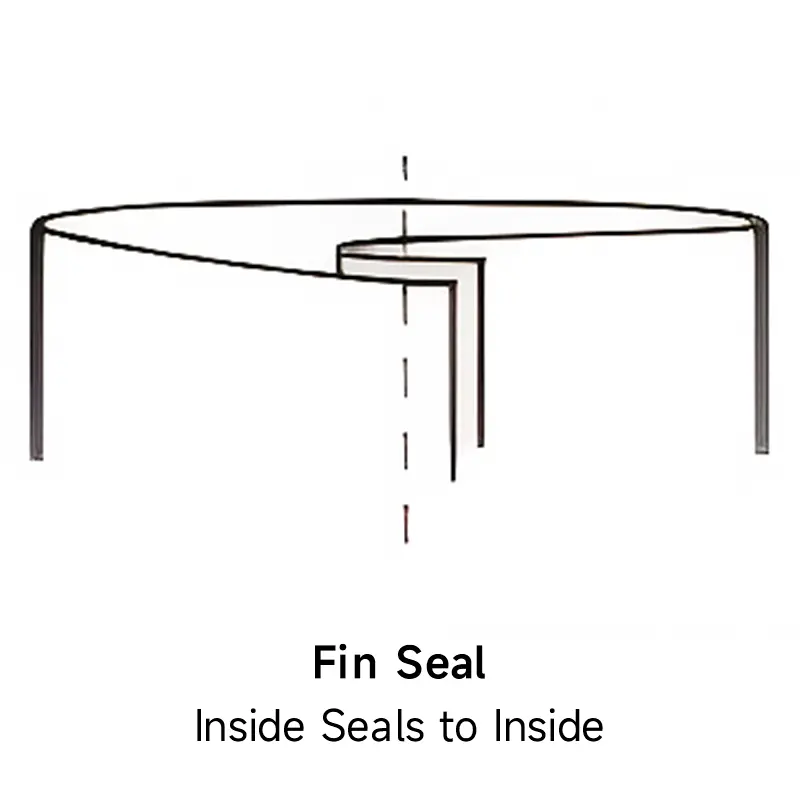

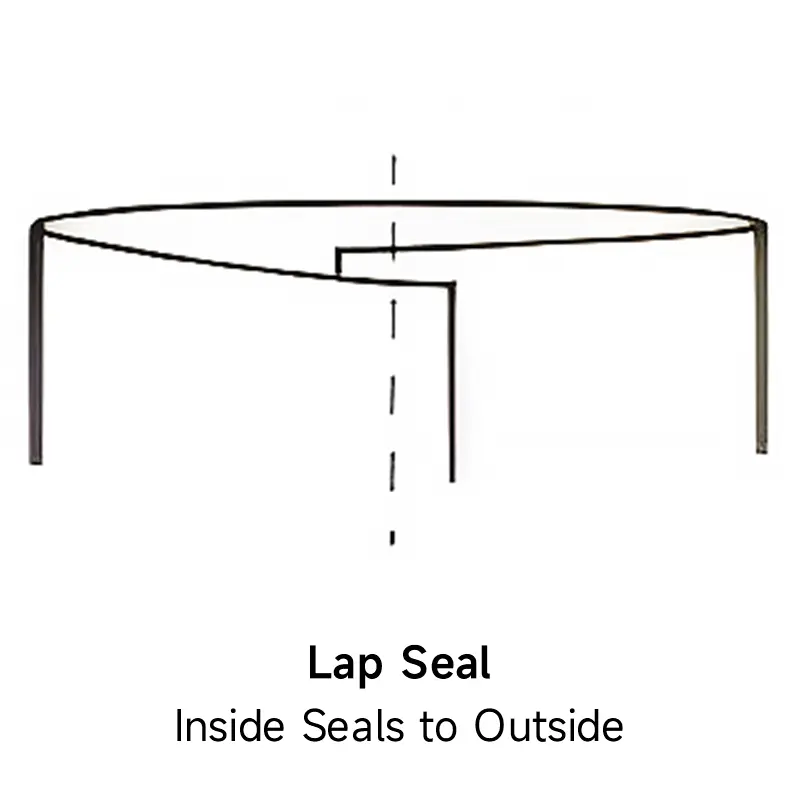

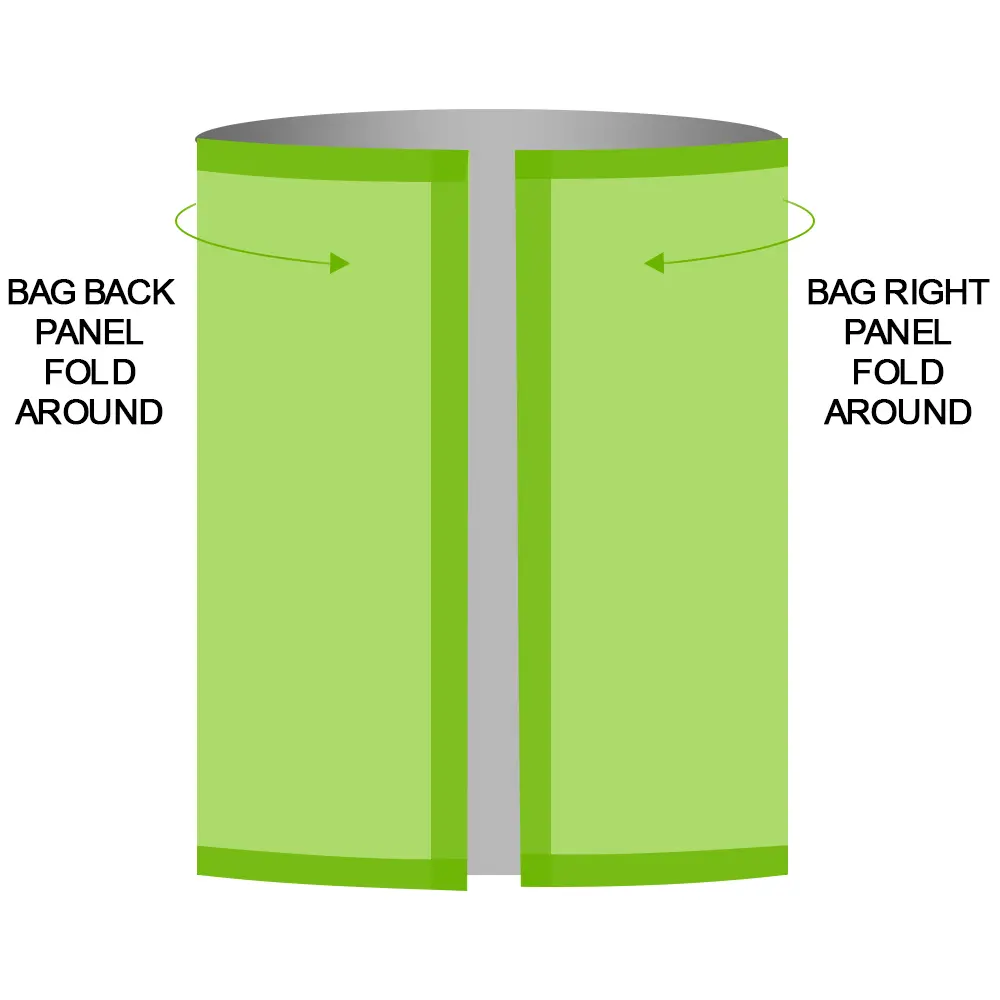

Common Back Sealing Option

Fin seal is created when two layers of film are sealed together along their edges to form a tube or pouch. The seal is made by folding one edge of the film over the other and applying heat and pressure to create a bond edge.

Lap seal is made by simply laying one edge of the film over the other and sealing them together without creating a fin. The edges are overlapped and heat-sealed to form a flat, seamless appearance. This type of seal is commonly used in flat bottom pouches, pillow pouches, and three side seal pouches. Lap seals are preferred when a smooth, uninterrupted surface is desired for packaging.

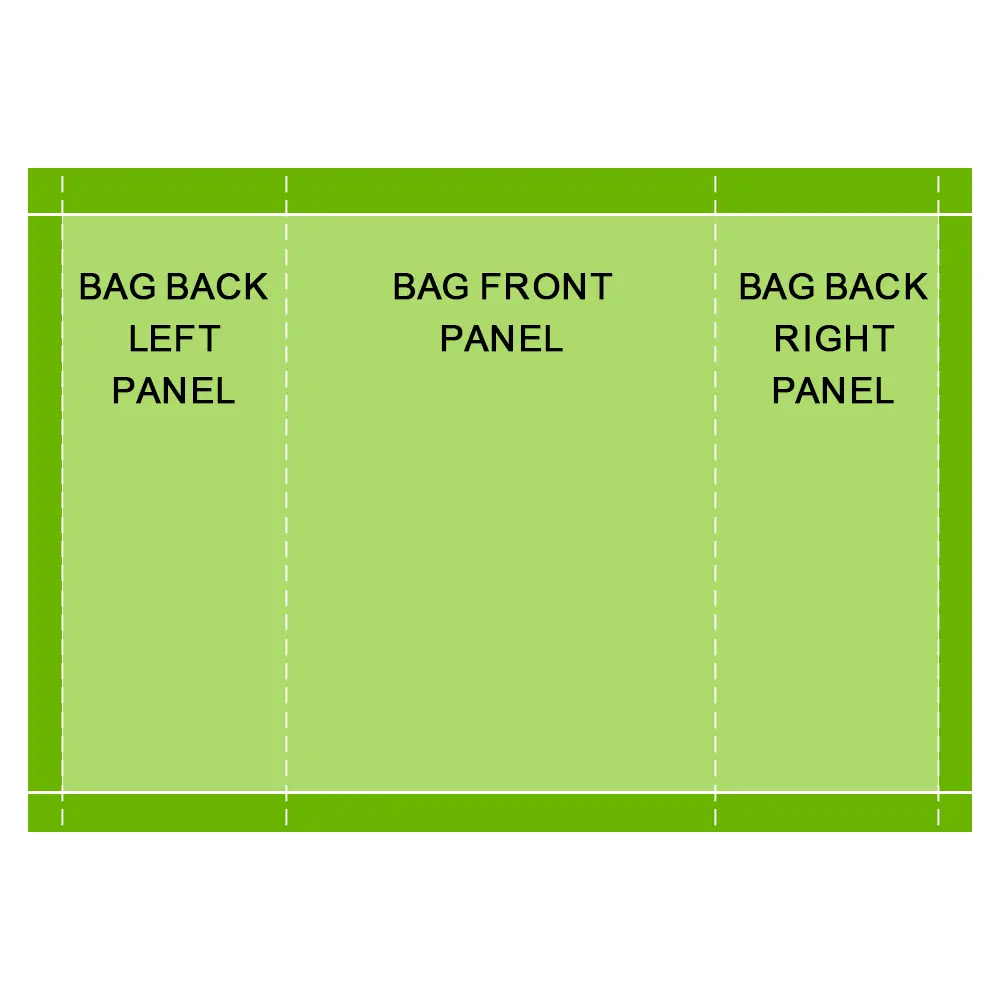

Printing Area and Sealing

Custom Process of Stand Up Pouch

1. Initial Consultation

We start with a detailed discussion to understand your packaging needs. This helps us define the specifications for your stand up pouches.

2. Design and Material Selection

As soon as we have your requirements, we’ll work with your design to create a pouch that meets your needs. We can help you develop the design from scratch to completion, ensuring it aligns perfectly with your vision. We offer a wide selection of materials to suit your products, ensuring your pouch is both functional and vivid appealing.

3. Sample Production

Before full-scale production, we will produced a sample pouch. This allows you to see and feel the product, ensuring it meets your standards.

4. Feedback and Adjustments

We value your feedback on the sample. We will make the necessary changes to the design or materials if adjustments are needed.

5. Full-Scale Production

After the sample is approved, we begin full-scale production of your stand up pouches. Our advanced machinery ensures high-quality output.

6. Quality Control

High quality standards are ensured with strict quality checks on every pouch. This step is crucial to ensure you receive the best product possible.

7. Packaging and Shipping

As a final step, we package your pouches carefully and ship them in the right packaging to you. Our logistics department will ensure that your order arrives on time and in perfect condition, and we also provide EXW services.

Artwork Process

We will review all your artwork designs and convert them into print-ready files. There are many technical considerations when printing barrier films, and we will handle all of these tasks for you. We will take your original artwork files and set them up for printing to ensure you get the best quality print, and develop digital art proofs that you can modify. KaleadPack focus on providing packaging that meets your requirements and budget.

Printing Method of Stand Up Pouch

There are two printing methods that KaleadPack offer, including:

- Gravure Printing: involves engraving the image onto a cylinder. It is known for its high-quality print and is cost-effective for large runs but has higher setup costs for short runs.

- Digital Printing: doesn’t require printing plates, allowing for lower setup costs and making it ideal for short runs, variable data, and customization.

| Digital Printing | Rotogravure Printing |

|---|---|

| Advantage: | Advantage: |

| No setup costs. | Lower per-unit cost than digital printing. |

| Shortest lead-times. | It is the most economical choice when scaling your business. |

| Great for start-ups and seasonal SKUS. | All Finish options are available. |

| Higher costs. | One-Time Plate costs. |

| Not advised for higher quantities. | Exceptional print durability and better ink opaqueness. |

| Limited finish options and printing effects. | |

| Unable to exact color match PMS colors and some other ink limitations. | |

| Shortcoming: | Shortcoming: |

| Higher costs. | One-Time Plate costs. |

| Not advised for higher quantities. | Exceptional print durability and better ink opaqueness. |

| Limited finish options and printing effects. | |

| Unable to exact color match PMS colors and some other ink limitations. | |

| MOQ : | MOQ : |

| 1000 Pcs | 10000 Pcs |

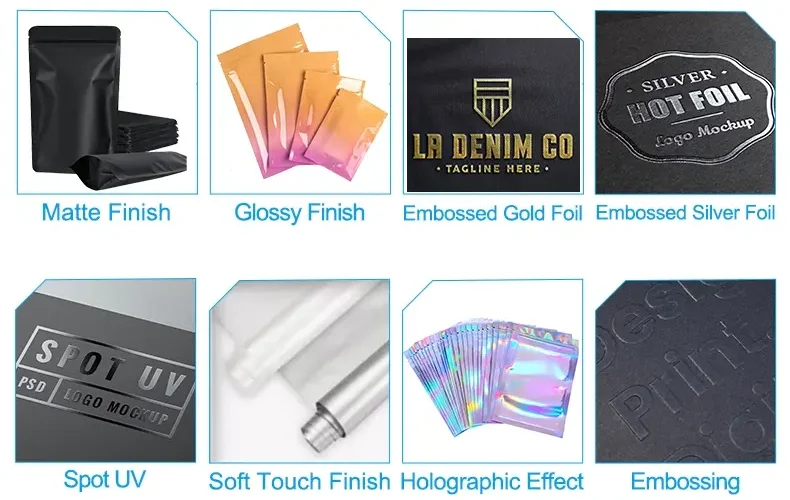

Finish Choices

Matte and gloss finishes offer different looks and feels. Matte gives a smooth, non-shiny appearance. Gloss is shiny and reflective.

Shipping Details

Once production is completed, the pouches are secured in a carton. Proper packaging prevents damage during transit.

You can expect timely delivery of your order. Shipping typically takes 2-3 weeks by sea, depending on your location. Tracking information is provided to monitor the shipment.

Kaleadpack partners with reliable carriers. This ensures your products arrive safely and on time. We deliver your packaging with care and precision.

What industries are suited to Pillow Pouches?

- Snacks: Chips, nuts, and popcorn.

- Coffee: Ground coffee or coffee beans.

- Freeze-Dried Foods: Fruits, vegetables, and meats.

- Spices and Condiments: Salt, pepper, and seasoning mixes.

- Pharmaceutical Products: Tablets, capsules, and powders.

- Supplements: Liquid or powder supplements.

- Toys: Small toys and accessories.

- Cosmetics and Personal Care Items: Lotions, creams, and facial masks.

- Sensitive Electronic Equipment: To prevent damage and contamination.

- Industrial Applications: Various types of liquids, solids, and powders.

- More Industries: Contact Us

Packaging Types

Food Packaging

Non-Food Packaging

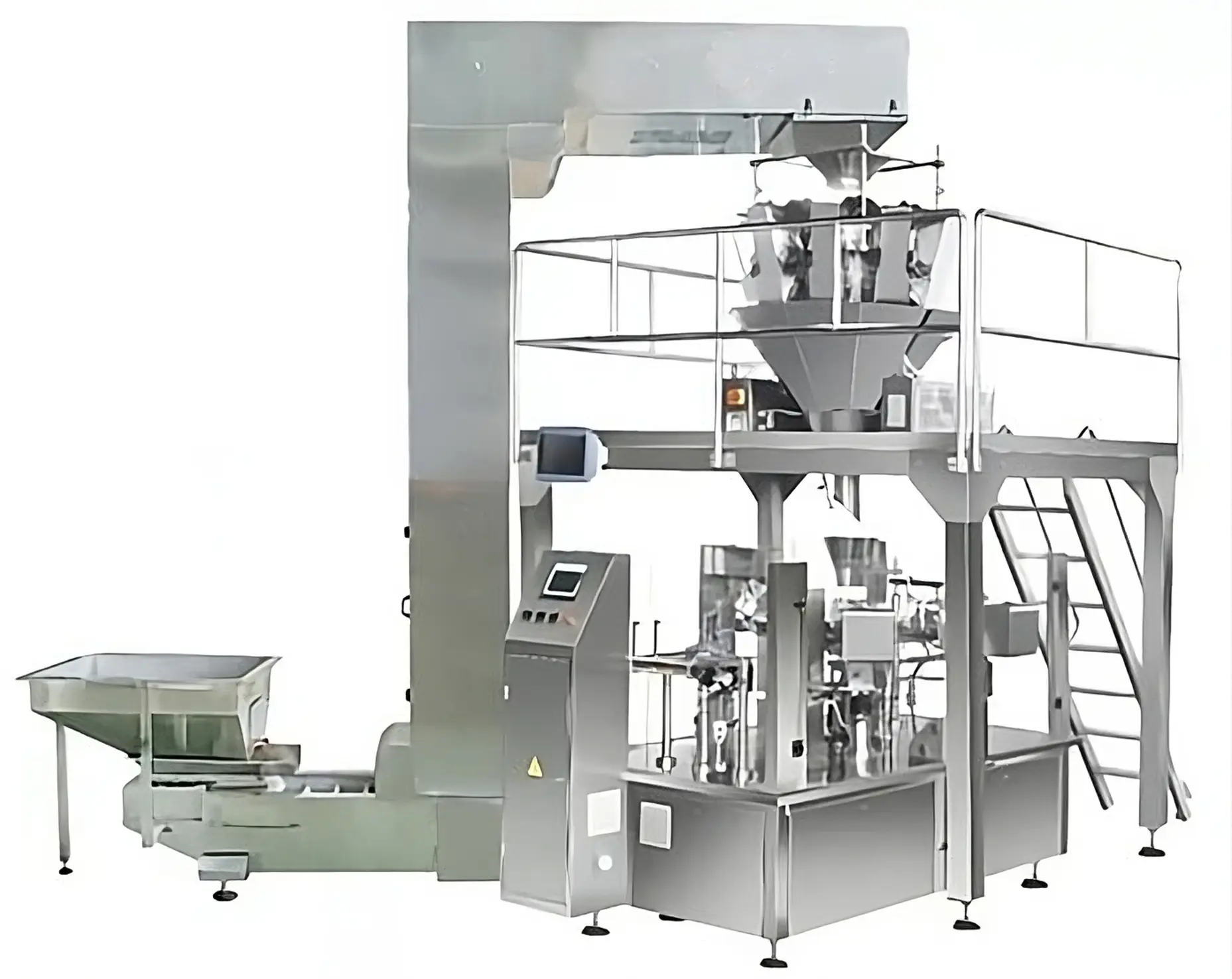

Applicable Machinery

The packaging industry utilizes a range of machinery to meet the diverse packaging needs of different products. The Collar Type Packing Machine (VFFS) and Horizontal Flow Wrap Machine (HFFS) are popular for packaging Pillow Pouch Bags. Below is an overview of these machines along with their key features and advantages:

Collar Type Packing Machine (VFFS):

- Speed and Efficiency: VFFS machines are known for their high-speed packaging capabilities, making them suitable for operations that require quick packaging solutions.

- Versatility: These machines can handle a wide range of product types and sizes, making them a versatile choice for different packaging needs.

- Seal Integrity: The VFFS machines provide strong seal integrity ensuring the packaged product is well-protected and remains fresh.

- Ease of Operation: Modern VFFS machines come with user-friendly interfaces making them easy to operate, even for individuals with minimal technical knowledge.

Horizontal Flow Wrap Machine (HFFS):

- Continuous Packaging: HFFS machines offer continuous packaging solutions, ideal for operations with high-volume packaging needs.

- Product Handling: They provide gentle handling of the product, ensuring it remains intact and undamaged during the packaging process.

- Compact Footprint: HFFS machines have a compact design making them suitable for operations with limited space.

- Low Maintenance: They are known for their low maintenance requirements, thus reducing the downtime and operational costs.

Our Services

Shipping Methods: Rollstock & Pre-cut Pillow Pouch Bag

When it comes to packaging, the method of shipping plays a crucial role in ensuring the efficiency and effectiveness of the packaging process. Two common shipping methods for Pillow Pouch Bags are Rollstock and Pre-cut Packaging. Below is a detailed description of these methods and how they cater to varying packaging and branding needs:

Rollstock:

- Bulk Packaging: Rollstock is a bulk packaging solution where the material is supplied in rolls. This method is suitable for high-volume packaging needs as it allows for continuous packaging without the need for frequent reloads.

- Cost-Effectiveness: Due to its bulk nature, Rollstock is often a more cost-effective solution as it reduces the per-unit cost of packaging.

- Custom Printing: Rollstock allows for custom printing across the length of the roll, providing an opportunity for consistent branding and design.

- Flexibility: The flexibility of Rollstock makes it adaptable to various packaging machines, aiding in seamless operations and reducing downtime.

Pre-cut Pillow Pouch Bag

- Precision: Pre-cut packaging involves the use of pre-cut and pre-sealed bags, ensuring precision and uniformity in packaging.

- Time-Saving: This method is time-saving as the bags are ready to be filled, eliminating the need for machine setup and adjustments.

- Quality Assurance: Pre-cut packaging allows for quality checks before filling, ensuring that each bag meets the required standards.

- Brand Enhancement: The pre-cut bags can be custom printed to enhance brand visibility and consistency across all products.

Why Choose Kalead Pack

KaleadPack is a Chinese company that provides one-stop flexible packaging solutions, including flexible packaging bags, rollstock, and packaging machines. We specialize in offering high-quality certified packaging and support global shipping. Our products are versatile, customizable, and perfect for a range of industries, offering good prices and high quality.